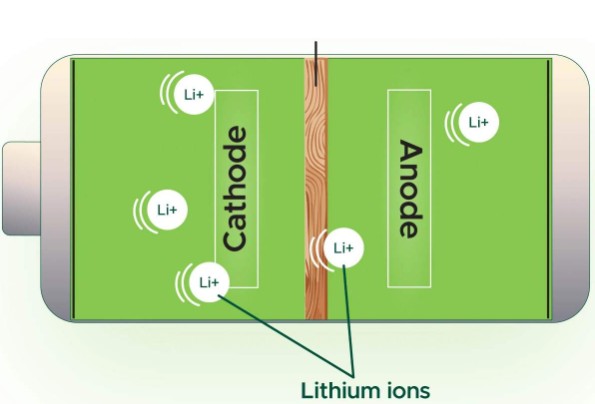

A team of researchers from Michigan State University (MSU) has developed a lignin-based material, derived from wood, that can enhance the safety and extend the lifespan of lithium-ion batteries. These batteries are found in most electronic devices, from mobile phones to electric vehicles, and their widespread use presents increasingly urgent environmental and safety challenges.

The new innovation replaces conventional plastic separators, which are prone to degradation at high temperatures, with ultra-thin lignin films. This natural, abundant, and renewable biopolymer offers greater thermal stability without shrinking or losing integrity even at 300°C—a significant improvement over the current limits of commercial separators.

More Safety, More Durability, Less Impact

This material not only prevents short circuits that could lead to fires but also increases battery lifespan by 60% by improving internal stability during charge and discharge cycles. An unexpected finding that, according to researchers, could translate into longer-lasting devices, fewer replacements, and thus, less electronic waste.

Additionally, the manufacturing process uses a dry processing method, eliminating the need for toxic solvents or chemical treatment stages. This means the separator’s production generates no hazardous waste or polluting emissions—a key advantage over current industrial techniques.

A Natural Resource with Scalable Applications

Lignin, particularly in its lignosulfonate form, is obtained as a byproduct in the paper and biomass processing industries. It is cost-effective, readily available, and does not compete with food crops, making it suitable for scalable and sustainable industrial production. This advancement directly aligns with global efforts to decarbonize the energy industry and reduce reliance on fossil-based materials.

Trendsetting Examples

This type of innovation aligns with recent developments like circular economy programs for batteries in Europe, driven by the EU Battery Regulation, which mandates minimum recycled content and safer, more sustainable designs starting in 2027. It also supports the push for conflict-free critical raw materials, a key factor in climate goals and energy independence.

Potential

The use of renewable materials like lignin could be a game-changer in the energy transition. Its implementation in batteries would enable:

Reducing the carbon footprint of the electronics and automotive industries.

Decreasing dependence on petroleum-based plastics.

Extending device lifespans, prolonging usage time, and reducing environmental impact.

Facilitating cleaner production, free of chemical waste, suitable for circular manufacturing models.

Boosting local and industrial innovation by utilizing byproducts from sectors like forestry and paper production.

This breakthrough is another step toward integrating bioeconomy into advanced technological solutions, proving that sustainability and high performance can not only coexist but also reinforce each other.

Source:Ecoinventos

Comments (0)

No comments yet. Be the first to comment!

Leave a comment