In the pursuit of developing safer and more sustainable electric cars, science has stumbled upon a solution that sounds like a joke... but it isn’t. A team of Austrian engineers has developed a battery casing that combines wood and steel, and the result is as revolutionary as it is unexpected.

This casing not only reduces the carbon footprint but also offers better protection against impacts and fire compared to current aluminum structures. To prove it, tests were conducted against the Tesla Model S, one of the best-selling electric cars.

It may sound strange, but wood—which we typically associate with something that burns easily—has proven to be safer than aluminum in certain extreme situations. Specifically, in impact tests in Graz, battery casings made with wood on the inside and steel on the outside absorbed up to 98% more energy than aluminum ones.

This is due to wood’s cellular structure, made up of small cells that collapse upon impact, helping dissipate the force more effectively. And when it comes to fires, this casing also surprises: In a test simulating a battery fire burning at over 1,300°C, the Bio!Lib structure, reinforced with a layer of natural cork, maintained a temperature 100°C lower on the side opposite the fire compared to an aluminum casing like those used by Tesla.

Essentially, it works because cork, when burned, carbonizes and creates an insulating layer that slows heat transfer into the car’s interior. The results have even surprised researchers at Graz University of Technology, whose project, named Bio!Lib, has long demonstrated that natural materials and design have much to offer electric mobility.

Advances like this are significant, especially when looking back at cases of electric car fires like the Chevrolet Bolt, which forced manufacturers to recall thousands of units and even halt production.

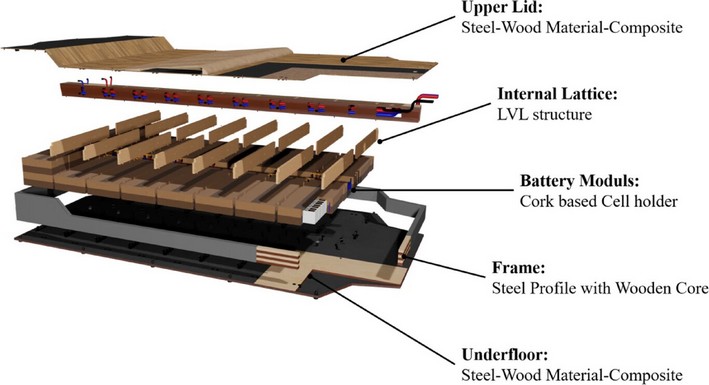

Battery casings are critical components in any electric car: besides protecting the modules from impacts or collisions, they must also withstand extreme temperatures and prevent fire spread in case of thermal failure. Until now, aluminum has been the preferred material due to its lightness and strength... but its production requires significant energy and resources, leaving a notable ecological footprint.

This is where the hybrid steel-and-wood solution gains points. The TU Graz team calculated the environmental impact of Bio!Lib in collaboration with the Wegener Center for Climate and Global Change, and the results are clear: the hybrid casing is more efficient in nearly all categories, from water consumption to associated emissions. Only in land use does aluminum win—predictable, given that wood requires space to grow.

What type of wood was used and why. Researchers have used sustainable woods like poplar, birch, or paulownia: they grow fast, are lightweight, and have excellent properties. They are also exploring whether low-value or reused wood could be viable, which would make use of underutilized resources and further reduce the system’s environmental impact.

The design is also part of the secret: a thin steel sheet wraps around the wood like a skin, welded directly onto the core. This combination creates a rigid yet lightweight structure that performs surprisingly well under deformation.

This new approach, based on renewable materials and hybrid techniques, aligns with growing pressure to decarbonize the entire electric vehicle production chain. And though it may seem crazy, we’ve seen other "crazy" innovations become standard—from Mercedes’ use of natural hemp fibers to BMW’s interior panels made from recycled materials.

Next Steps: Recyclability and Mass Production

The Graz research team is already working with industrial partners to evaluate mass production of Bio!Lib and is analyzing how to improve the recyclability of cork and the hybrid composite itself. The key will be developing scalable and cost-effective processes that allow manufacturers to adopt these solutions without compromising costs or performance.

Meanwhile, other brands are exploring similar paths. Volvo, for example, already uses fossil-free steel in its batteries, and more manufacturers are betting on circular economy strategies and biofabricated materials to enhance sustainability without sacrificing safety.

Source:Motor Pasion

Comments (0)

No comments yet. Be the first to comment!

Leave a comment